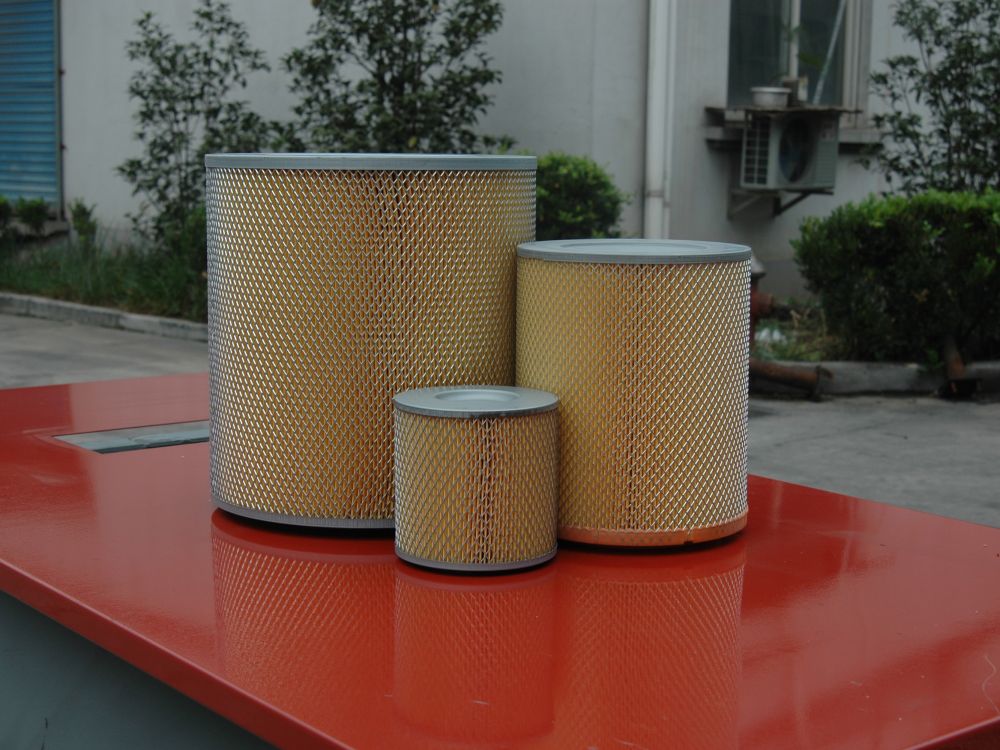

Isihlungi Se-Screw Air Compressor Oil Separator Isihlungi Samafutha Esihlungi

Isihlungi somoya

Isihlungi somoya siyingxenye ehlunga uthuli lomoya kanye nokungcola, futhi umoya ohlanzekile ohlungiwe ungena egunjini lokuminyanisa isikulufu ukuze ucindezelwe.Ngenxa yokuvunyelwa kwangaphakathi komshini oyisikulufa, izinhlayiya kuphela ezingaphakathi kuka-15u ezivunyelwe ukuhlunga.Uma isici sesihlungi somoya sivalekile futhi sonakalisiwe, inani elikhulu lezinhlayiya ezinkulu kune-15u zizongena emshinini wesikulufa futhi zijikeleze, okungeke kufinyeze kakhulu impilo yesevisi yesici sokuhlunga uwoyela kanye nomgogodla wokuhlukanisa uwoyela negesi, kodwa futhi kubangele. inani elikhulu lezinhlayiya ukungena ngokuqondile emgodini wokuzala, okuzosheshisa ukugqoka okuthwala futhi kwandise imvume ye-rotor.Ukusebenza kahle kokucindezela kuyancipha, futhi ngisho ne-rotor yomile futhi ibanjwe.

Isihlungi samafutha

Ngemuva kokuthi umshini omusha usebenze amahora angama-500 okokuqala, ingxenye yesihlungi sikawoyela kufanele ishintshwe.Sebenzisa isikrufu esikhethekile ukuze uhlehlise isici sokuhlunga uwoyela ukuze usisuse.Kungcono ukwengeza isipholile somshini wesikulufa ngaphambi kokufaka isici esisha sokuhlunga.Khipha into yokuhlunga uyibuyisele esihlalweni sokuhlunga uwoyela ngezandla zombili bese usiqinisa siqine.Kunconywa ukuthi umiselele isici esisha sokuhlunga njalo ngamahora angu-1500-2000.Kungcono ukufaka esikhundleni sesici sokuhlunga uwoyela ngesikhathi esifanayo lapho ushintsha isipholile.Uma imvelo inokhahlo, umjikelezo wokushintsha kufanele ufinyezwe.Kunqatshelwe ngokuphelele ukusebenzisa isici sokuhlunga amafutha ngaphezu komkhawulo wesikhathi, ngaphandle kwalokho, ngenxa yokuvinjelwa okukhulu kwesici sokuhlunga uwoyela, umehluko wengcindezi udlula umkhawulo wokubekezelela we-valve yokudlula, i-valve yokudlula izovuleka ngokuzenzakalelayo, futhi i-valve enkulu. inani lokungcola nezinhlayiya zizongena ngqo ku-screw host ngamafutha, okubangela imiphumela emibi.

Isihlukanisi samafutha

Isihlukanisi somoya kawoyela siyingxenye ehlukanisa uketshezi olupholile lomshini oyisikulufa emoyeni ocindezelwe.Ngaphansi kokusebenza okujwayelekile, impilo yesevisi yesihlukanisi somoya kawoyela cishe amahora angama-3000, kepha ikhwalithi yamafutha okugcoba kanye nokunemba kokuhlunga komoya kunomthelela omkhulu empilweni yawo.Kungabonakala ukuthi ukugcinwa nokushintshwa komjikelezo wesici sokuhlunga umoya kufanele kufinyezwe ezindaweni zokusebenza ezinokhahlo, futhi ngisho nokufakwa kwesihlungi somoya ngaphambili kufanele kucatshangelwe.Isihlukanisi sikawoyela negesi kufanele sishintshwe lapho siphelelwa yisikhathi noma umehluko wengcindezi phakathi kwangaphambili nangemuva udlule u-0.12Mpa.Uma kungenjalo, injini izogcwala ngokweqile, futhi isihlukanisi somoya kawoyela sizolimala futhi uwoyela uzovuza.Indlela yokushintsha: Khipha amalunga amapayipi okulawula afakwe kwikhava yombhobho kawoyela negesi.Khipha ipayipi lokubuyisela uwoyela elingena emgqonyeni kawoyela negesi kusukela esembozweni somphongolo kawoyela negesi, bese ukhipha amabhawodi okubopha ekhava engaphezulu yomphongolo kawoyela negesi.Susa isembozo esingaphezulu samafutha nesitsha segesi, futhi ukhiphe amafutha.Susa iphedi le-asbestos kanye nokungcola okunamathiselwe kwikhava engaphezulu.Faka isihlukanisi esisha sikawoyela negesi, unake amaphedi e-asbestos aphezulu naphansi kufanele ahlanganiswe futhi ahlanganiswe, futhi amaphedi e-asbestos kufanele abekwe ngobunono lapho ucindezela, ngaphandle kwalokho kuzodala ukugungiswa kwamaphedi.Phinda ufake ikhava engaphezulu, ipayipi lokubuyisela uwoyela, namapayipi okulawula njengoba abenjalo, futhi uhlole ukuvuza.

Ukushintsha Okupholisayo

Ikhwalithi yesipholisi somshini wesikulufa inomthelela omkhulu ekusebenzeni komshini wesikulufa ojovwe uwoyela.Isipholile esihle sinokuzinza okuhle kwe-oxidation, ukuhlukana okusheshayo, ukuhlanzwa kwegwebu elihle, i-viscosity ephezulu, nokusebenza okuhle kokuqeda ukugqwala.Ngakho-ke, abasebenzisi kufanele basebenzise i-Pure screw machine coolant.

Isipholile sokuqala kufanele sishintshwe ngemva kwamahora angu-500 okusebenza komshini omusha, futhi okokupholisa kufanele kushintshwe njalo ngemva kwamahora angu-3000 okusebenza ngemva kwalokho.Kungcono ukufaka esikhundleni sokuhlunga amafutha ngesikhathi esifanayo lapho ushintsha amafutha.Sebenzisa ezindaweni ezinezimo ezinzima ukuze unciphise umjikelezo wokushintsha.Indlela yokubuyisela: Qala i-compressor yomoya bese uyigijima imizuzu engu-5, ukuze izinga lokushisa likawoyela likhuphuke ngaphezu kuka-70 ° C futhi i-viscosity yamafutha iyancipha.Yeka ukusebenza, lapho kunengcindezi engu-0.1Mpa emgqonyeni kawoyela negesi, vula i-valve yokukhipha uwoyela ngaphansi komgqomo kawoyela negesi, bese uxhuma ithange lokugcina uwoyela.Ivalvu yokukhipha uwoyela kufanele ivuleke kancane ukuze kuvinjwe into epholile ngaphansi kwengcindezi kanye nezinga lokushisa ukuthi lingachaphazeli futhi lilimaze abantu nokungcola.Vala i-valve yokukhipha uwoyela ngemva kokuba isipholile siconsa.Khipha isici sesihlungi sikawoyela, khipha into epholisayo epayipini ngalinye ngesikhathi esifanayo, bese ufaka into entsha yokuhlunga uwoyela.Vula ipulaki yesikulufu sokugcwalisa uwoyela, faka uwoyela omusha, yenza izinga likawoyela libe phakathi kwebanga lesikali sikawoyela, qinisa ipulaki yesikulufu yesigcwalisi, futhi uhlole ukuvuza.Isipholisi kufanele sihlolwe njalo ngesikhathi sokusetshenziswa.Uma ulayini wezinga likawoyela utholakala uphansi kakhulu, isipholile esisha kufanele sigcwaliswe ngesikhathi.Amanzi ajiyile kumele akhishwe njalo ngesikhathi kusetshenziswa into epholile.Ngokuvamile, kufanele ikhishwe kanye ngesonto.Emazingeni okushisa aphezulu, kufanele kukhishwe izikhathi ezingama-2-3 kanye ngosuku.Yima isikhathi esingaphezu kwamahora angu-4, vula ivalvu yokukhulula uwoyela lapho kungekho ngcindezi emgqonyeni kawoyela negesi, khipha amanzi ajiyile, bese uvala ngokushesha i-valve lapho isipholile sibonakala siphuma.Kwenqatshelwe ngokuphelele ukuxuba izinhlobo ezahlukene zokupholisa, futhi kwenqatshelwe ngokuphelele ukusebenzisa izinto zokupholisa isikhathi eside, ngaphandle kwalokho ikhwalithi yesipholisa izokwehla, ukuthambisa kuzoba mpofu, futhi indawo ye-flash izokwehliswa. izobangela kalula ukuvalwa kwezinga lokushisa eliphezulu kanye nokusha kukawoyela okuzenzakalelayo.

Isici sokuhlukanisa uwoyela

1. I-porosity ephezulu, i-permeability enhle kakhulu, ukwehla kwengcindezi ephansi nokugeleza okukhulu

2. Umthamo omkhulu wokubamba uthuli, ukunemba okuphezulu kokuhlunga, umjikelezo omude wokushintsha

3. Ukugqwala nokumelana nokushisa okuphezulu

4. Igagasi eligoqekayo landisa indawo yokuhlunga

5. Phezulu Ngisho noma ukugeleza komoya kuphephezela ngamandla, i-fiber ngeke iwe futhi isenamandla aphezulu.

Izihlungi Zomoya

Thuthukisa ukugeleza komoya okushelelayo nokungcoliswa okuncane kakhulu.

Ukugeleza komoya okubushelelezi, okuhlanzekile kusiza ukunciphisa izindleko zamandla, ukulondoloza uketshezi nokwelula ukuphila komoya

Iphepha lokuhlunga eliklanywe ngendlela ehlukile elinama-indentations licupha izinto zakwamanye amazwe ngaphandle kokuvimbela ukugeleza komoya okungenayo, okwandisa ukusebenza kahle.

Ukusebenza kahle kwesihlungi: 99.99%

Isihlungi samafutha

1. Imidiya yomoya elungile ihlinzeka ngokusebenza kahle kakhulu.

2. Thuthukisa ukusebenza kahle kwe-compressor ngokuncishiswa kwe-air inlet.

3. Umthamo omkhulu wothuli, i-treble yemidiya evamile okungenani.

4. Ubuchwepheshe bokuhlunga ubuso benza ukugcinwa nokuvuselela kube lula.

5. Isiqinisekiso sokuvikela uwoyela we-lever ephezulu ekungcoleni, sandise impilo yezingxenye.